If your printer's nozzle is getting clogged it could lead to an overflow of filament which can cover your nozzle and hotend.

Guide to gently remove this:

- Remove the white cover over the hotend. This could be done with something sharp. Be aware that it can break if overbent.

- Press down on the hotend which is the entire silver cylinder. It should be hanging in the wires and not touch anything else.

- On the app choose "Change filament", and let the nozzle heat up. If the hotend is hanging too low, wind the middle metal rod until the printer arm is lifted enough.

- When the hotend has warmed up to about 40C try to remove the silicone cover. If she silicone cover is not coming off easily, then wait until the nozzle reaches 200C. You can use a tool to avoid getting burned.

- NOTE: Be careful to not rip the thin wires on side.

- When the nozzle is about 200C, gently wipe the hotend with paper towels. The filament should easily be removed when the hotend is hot. Be careful to not get burned. It is important that you are gentle around the wires.

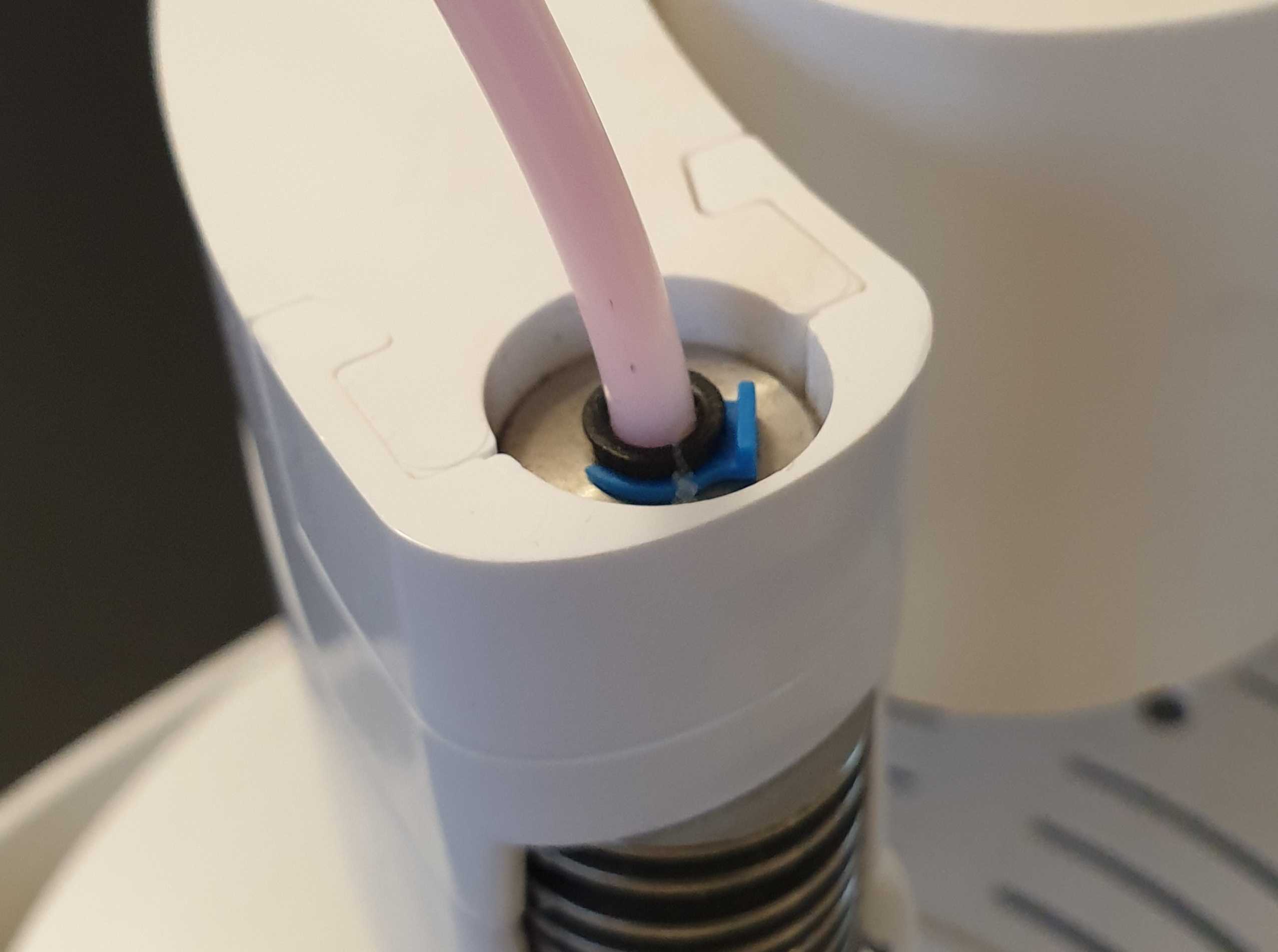

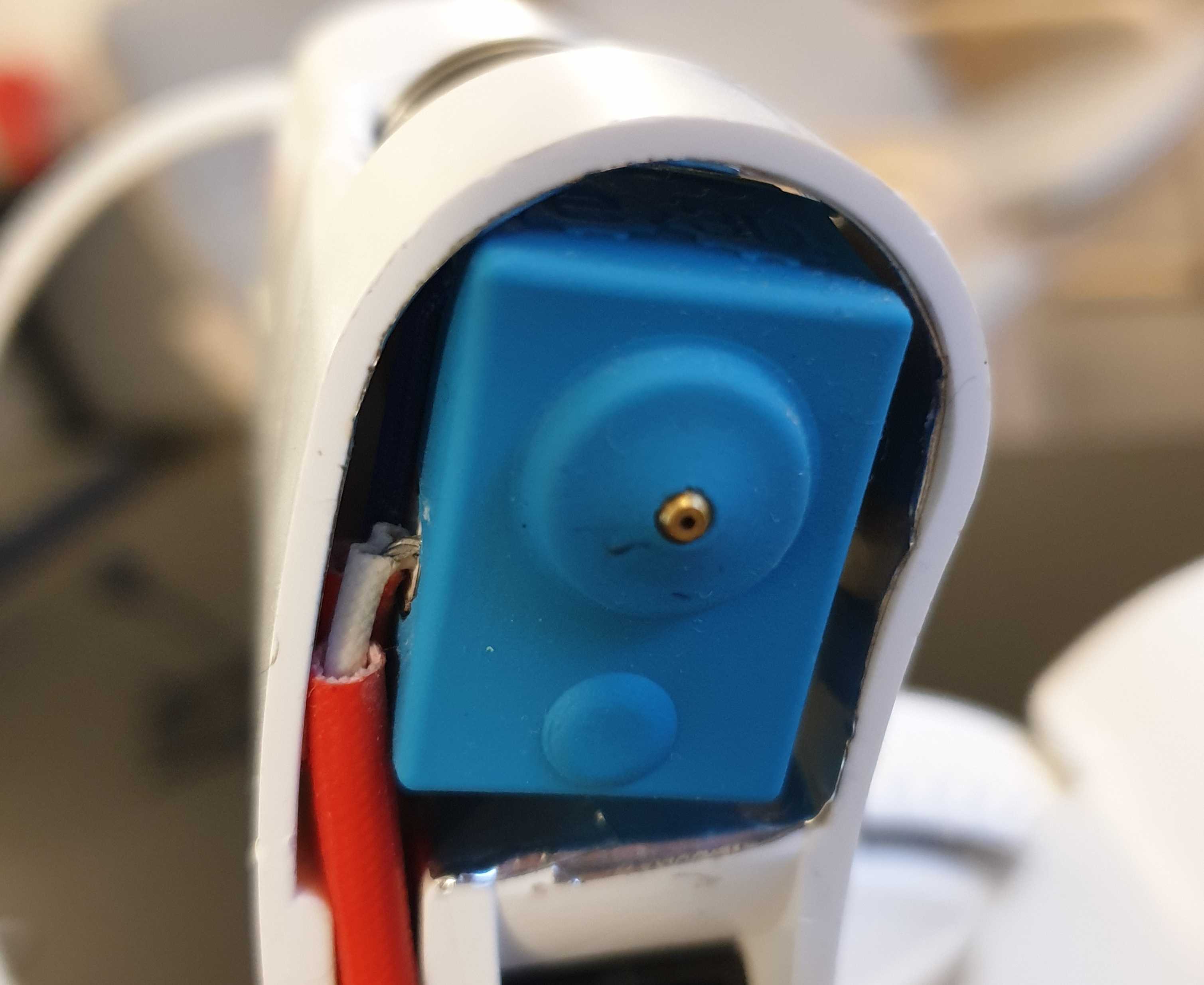

- When the melted filament is removed from the hotend and silicone cover, reassemble. The thin wires should be coming out of the holes in the silicone cover as the photo below.

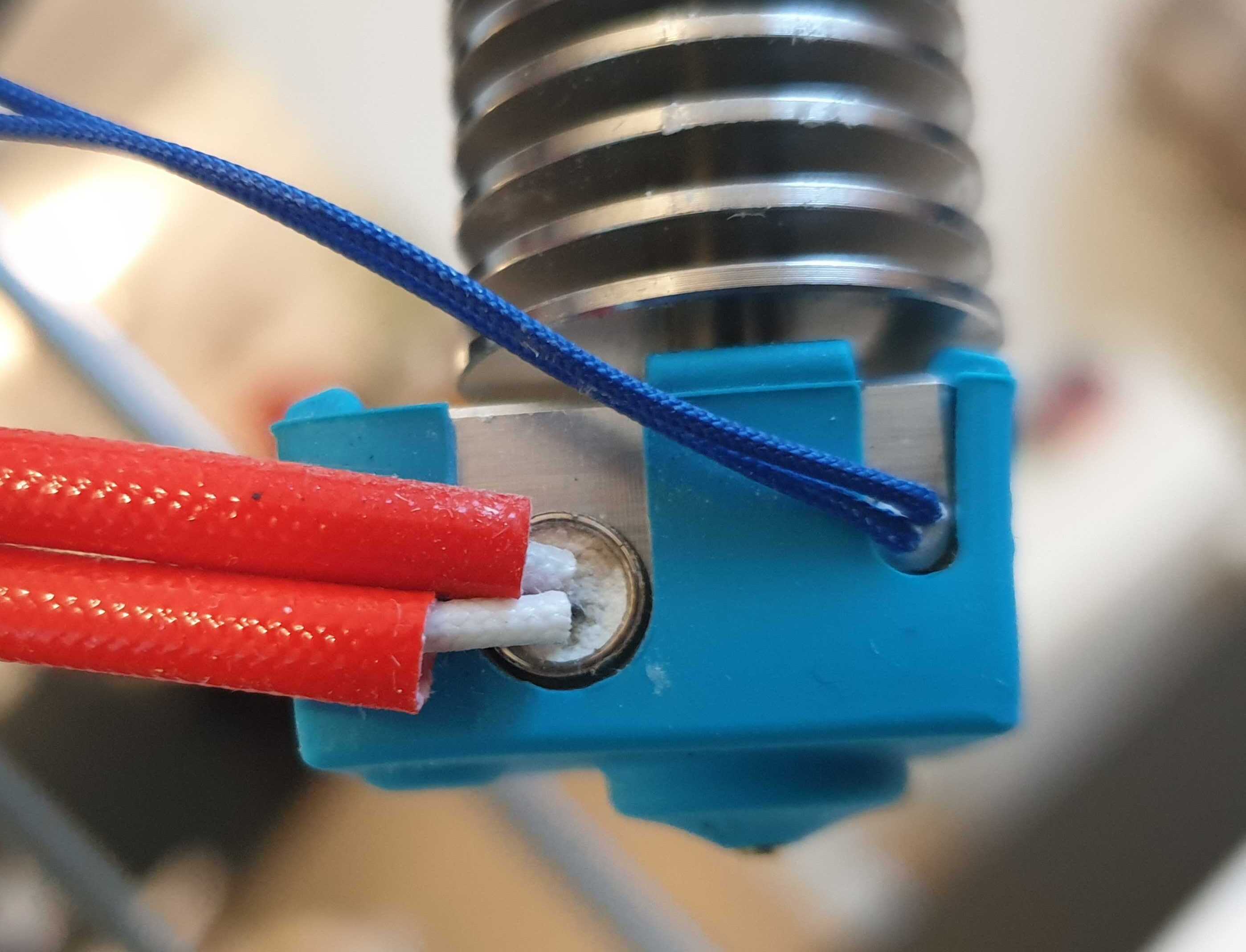

- The wires should be placed in gap along the arm as the photo below.

Comments

0 comments

Please sign in to leave a comment.